Carbon black from tire pyrolysis

Carbon black is a fine, black powder produced from the pyrolysis (thermal decomposition) of tires. Tire pyrolysis involves heating scrap tires in the absence of oxygen, causing them to break down into various byproducts, one of which is carbon black.

During the pyrolysis process, the rubber compounds within the tires are heated to high temperatures, leading to the release of volatile gases and the formation of solid residue. The solid residue primarily consists of char, which is further processed to obtain carbon black.

Carbon black obtained from tire pyrolysis is composed of elemental carbon and small amounts of other elements such as hydrogen, sulfur, nitrogen, and oxygen. It has a highly complex structure with a large surface area, making it suitable for a wide range of applications.

Carbon black derived from tire pyrolysis finds uses in numerous industries, including tire manufacturing, rubber products, coatings, paints, inks, plastics, and more. Its properties, such as high tensile strength, good thermal conductivity, and excellent UV stability, make it a valuable industrial commodity. Additionally, utilizing carbon black from tire pyrolysis can contribute to recycling efforts and reduce waste sent to landfills or incineration.

Uses of carbon black from tire pyrolysis:

Carbon black from tire pyrolysis can be used as a raw material to produce steel reinforcement, fillers and colorants in the rubber and plastics industry. It can also be refined into higher quality carbon black.

Specification of carbon black from tire pyrolysis:

.png)

Product of carbon black from tire pyrolysis:

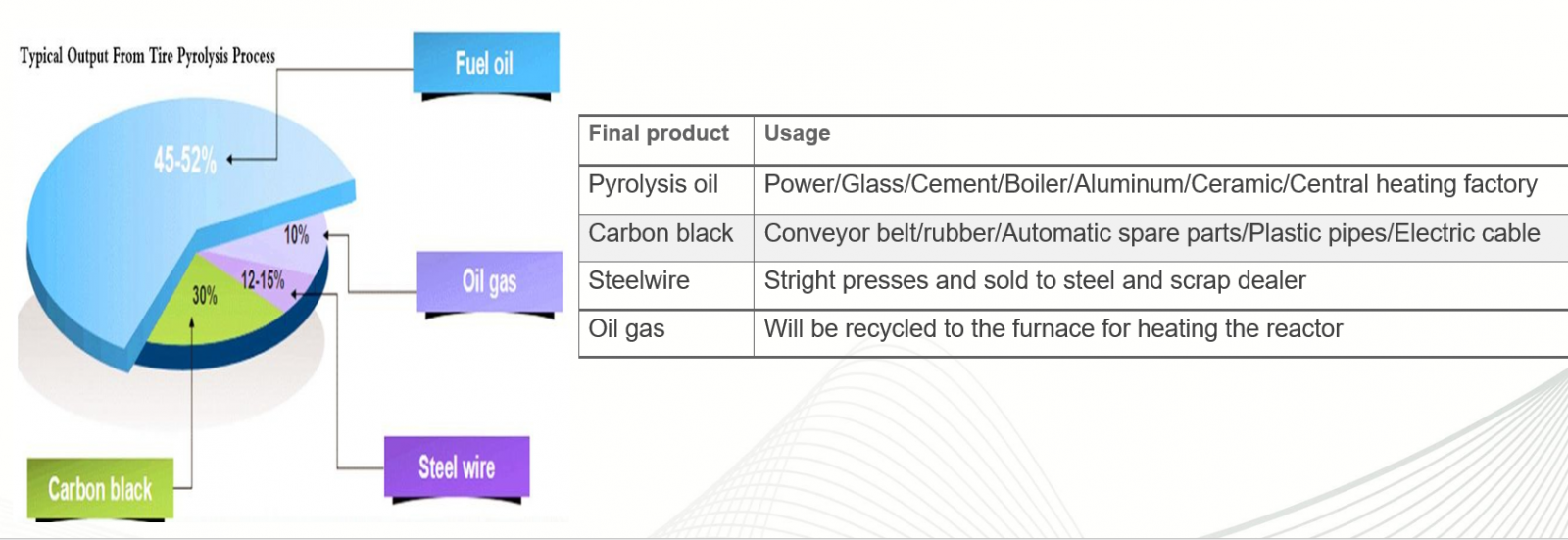

Carbon black (30-35%) of total production, which means you can get about 3-3.5 tons of pyrolysis fuel oil from 10 tons of waste tires.

The market price of carbon black from tire pyrolysis:

Regardless of any country, the price of carbon black from tire pyrolysis is always stable and high. You never need to worry about the market and carbon black prices.